INNOVATIVE PRODUCTS

RES OEM & Custom Equipment

RES are heavy equipment manufacturing and refurbishment specialists. Our team has extensive knowledge of mining heavy equipment, the standard of repair required and the importance of delivering on time, every time.

Learn more →

Buckets

Learn more →

Trays

Learn more →

Blades

Learn more →

General Fabrication

RES Trays

-

Once the rebuilt equipment is installed at your site, RES can perform on-site "Working Inspections." These inspections involve thickness testing and wear monitoring of equipment under real operational conditions to verify its performance and identify any potential issues that may arise in the field and or plan maintenance schedules.

-

Careful planning, problem-solving and innovative design resulted in reducing the lead time to manufacture 796 SDB Duratray down to 32 days.

-

Disassembly and Parts Replacement:

RES’ skilled team will disassemble the equipment, carefully removing worn-out or damaged components. Components are replaced with high-quality parts to restore the equipment's functionality and performance.

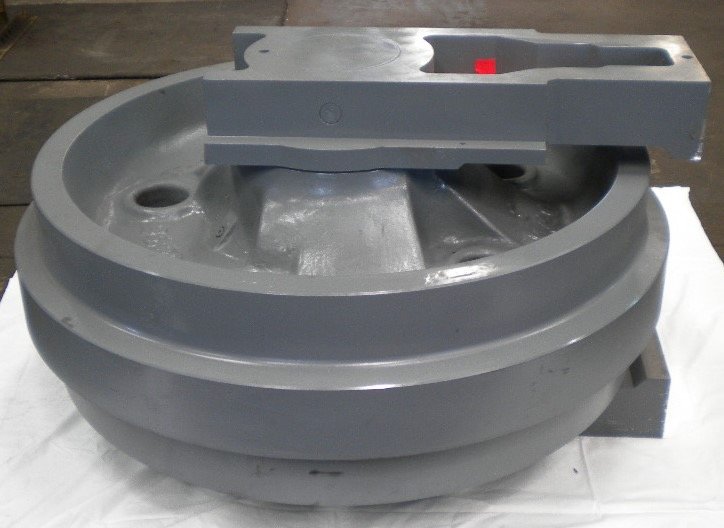

Dragline Buckets & Dipper Buckets

-

RES specialises in building and repairing buckets that significantly improve operational efficiency and uptime within mining and material handling activities. Our expertise lies in skilfully harmonising critical factors such as wear tendencies, load capacity, and bucket weights. This meticulous approach guarantees that both our builds and repairs adhere to the precise design parameters set by the original engineering manufacturers.

-

Our scope of services encompasses the manufacturing and repair of buckets spanning a range, from 2 m3 all the way up to 50 m3 for various sectors including mining, construction, and quarrying applications. RES prides itself on its commitment to engineering excellence, ensuring that each bucket worked on or built is optimised for peak performance, durability, and seamless integration into your operations.

-

We can scope up repairs on-site, problem-solve issues the site is having with the equipment, and provide custom-designed and certified solutions.

Specialised dozer blade builds and repairs

-

RES offers quality dozer blade repair solutions for the CAT D10 and high-capacity D11 blades for pushing overburden in mining operations. Dozer attachments are built and repaired for maximum durability.

-

Apart from repairs, RES can also offer structural conversions from SU-Blade to a U-Blade or U-Blade to SU-Blade for blade sizes from D9 to D11.

Repairs include;

• Full refurbishment of any type of blade including line boring.

• Replacement of front skins, mouldboard sections, endplates

• Repair of rock-guards

• Refurbishment of mounting points

• Replacement of wear plates

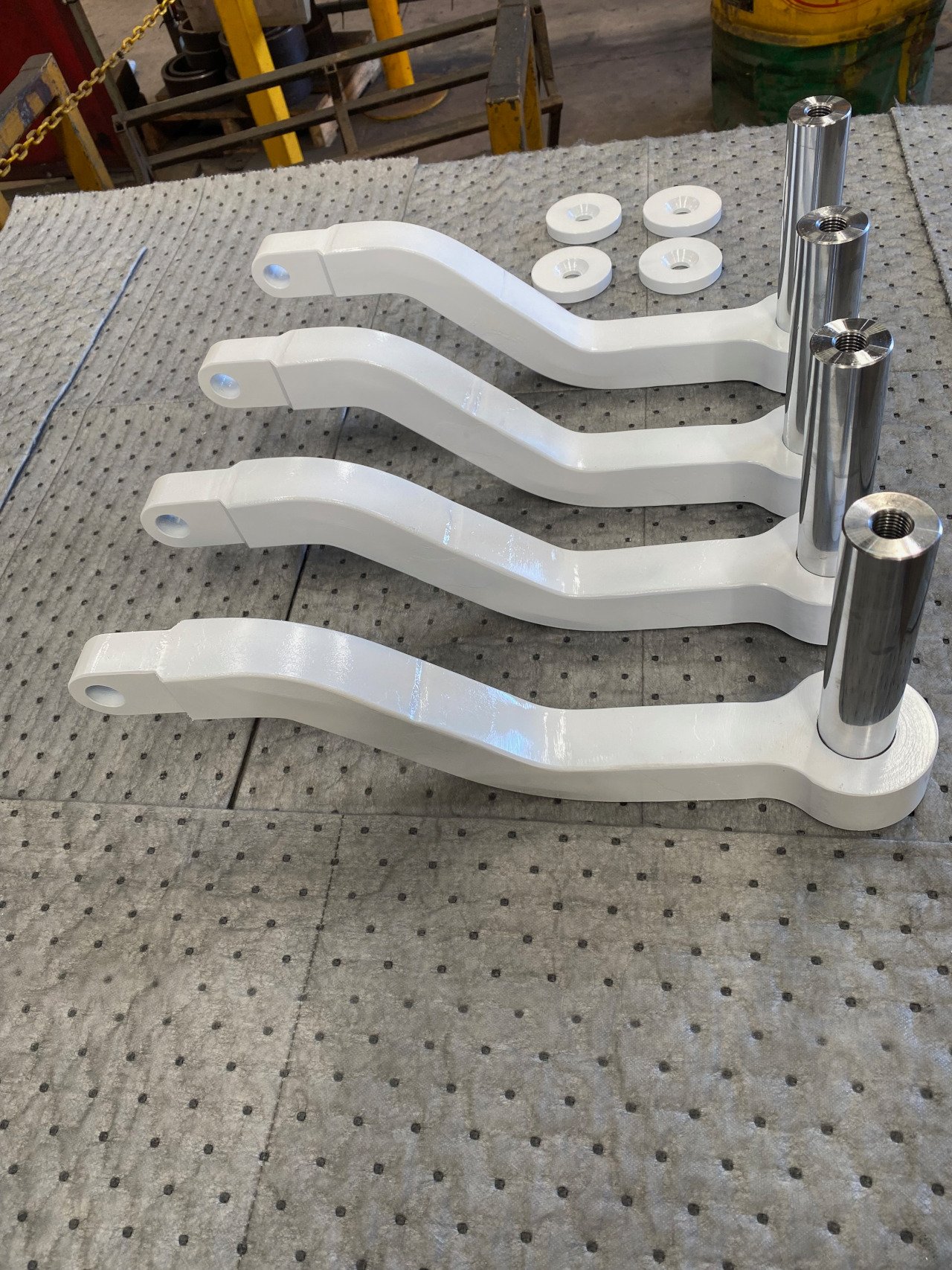

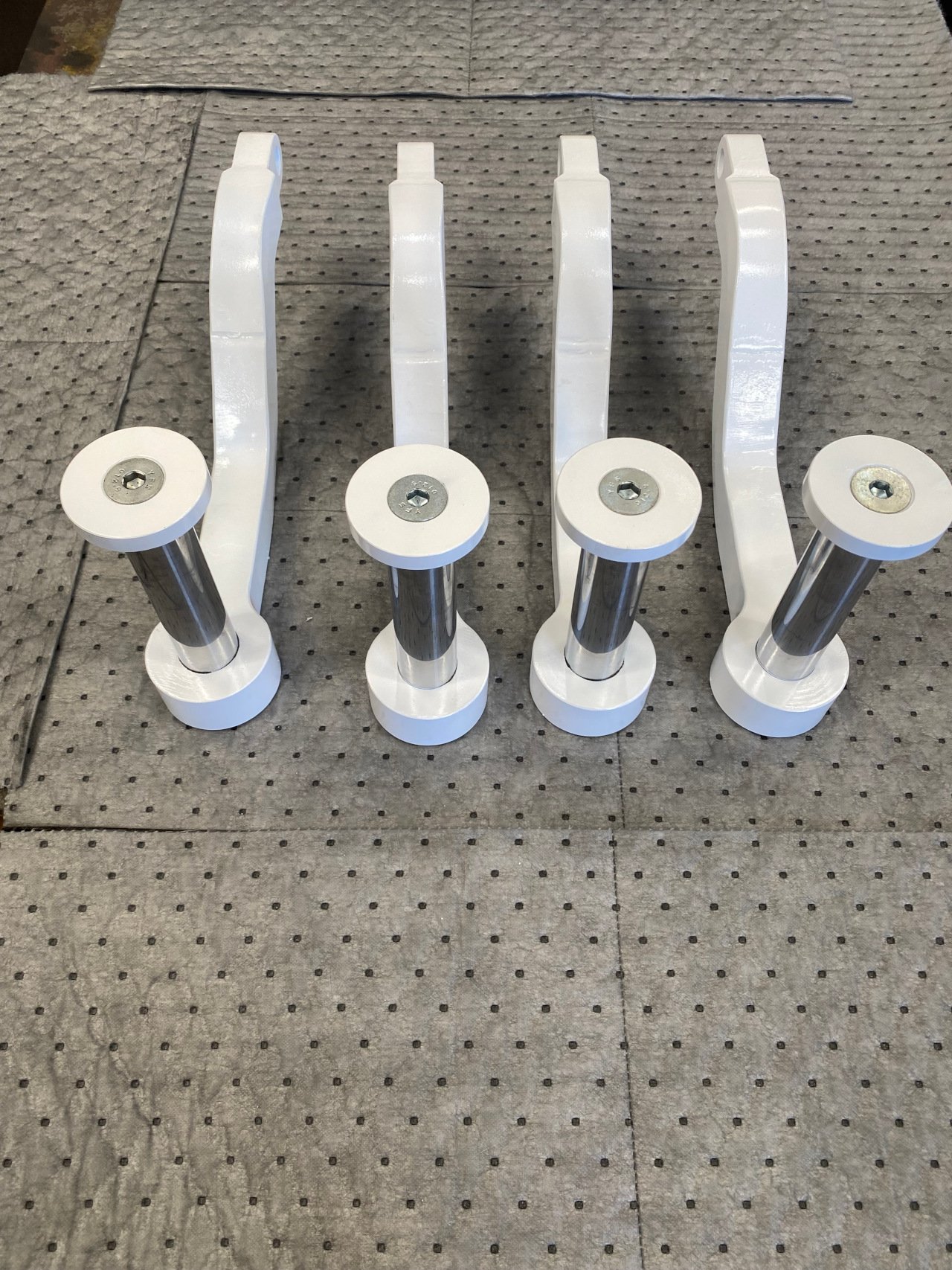

• Push-arm refurbishment

-

The Team at RES has extensive knowledge of mining heavy equipment, the standard of repair required and the importance of delivering on time, every time.

RES Fabrication and Engineering

-

Proficient in commercial and industrial engineering, fabrication, and welding, RES functions across all of Central Queensland. Their workforce comprises of experienced boilermakers, fitters, and skilled trade assistants, supported by fully-equipped mobile units accessible around the clock.

-

From emergency on-site repairs of heavy machinery through to custom design and fabrication of tools and parts, RES offers a complete range of engineering, fabrication and welding services. The team regularly service the mining, agriculture and construction industries.

-

In conjunction with welding and fabrication, RES also supplies qualified staff and equipment for hire at competitive rates. The RES Team are competent and friendly, with full OH&S and mining certificates.