INNOVATIVE PRODUCTS

RES OEM & Custom Equipment

Richie's Engineering Services are heavy equipment manufacturing and refurbishment specialists. Our team has extensive knowledge of mining heavy equipment, the standard of repair required and the importance of delivering on time, every time.

Learn more →

Buckets

Learn more →

Trays

Learn more →

Blades

Learn more →

General Fabrication

RES Trays

-

Once the rebuilt equipment is installed at your site, Richie’s can perform on-site "Working Inspections." These inspections involve thickness testing and wear monitoring of equipment under real operational conditions to verify its performance and identify any potential issues that may arise in the field and or plan maintenance schedules.

-

Careful planning, problem-solving and innovative design resulted in reducing the lead time to manufacture 796 SDB Duratray down to 32 days.

-

Disassembly and Parts Replacement:

Richie’s skilled team will disassemble the equipment, carefully removing worn-out or damaged components. Components are replaced with high-quality parts to restore the equipment's functionality and performance.

Dragline Buckets & Dipper Buckets

-

RES specialises in building and repairing buckets that significantly improve operational efficiency and uptime within mining and material handling activities. Our expertise lies in skilfully harmonising critical factors such as wear tendencies, load capacity, and bucket weights. This meticulous approach guarantees that both our builds and repairs adhere to the precise design parameters set by the original engineering manufacturers.

-

Our scope of services encompasses the manufacturing and repair of buckets spanning a range, from 2 m3 all the way up to 50 m3 for various sectors including mining, construction, and quarrying applications. RES prides itself on its commitment to engineering excellence, ensuring that each bucket worked on or built is optimised for peak performance, durability, and seamless integration into your operations.

-

We can scope up repairs on-site, problem-solve issues the site is having with the equipment, and provide custom-designed and certified solutions.

Specialised dozer blade builds and repairs

-

RES offers quality dozer blade repair solutions for the CAT D10 and high-capacity D11 blades for pushing overburden in mining operations. Dozer attachments are built and repaired for maximum durability.

-

Apart from repairs, RES can also offer structural conversions from SU-Blade to a U-Blade or U-Blade to SU-Blade for blade sizes from D9 to D11.

Repairs include;

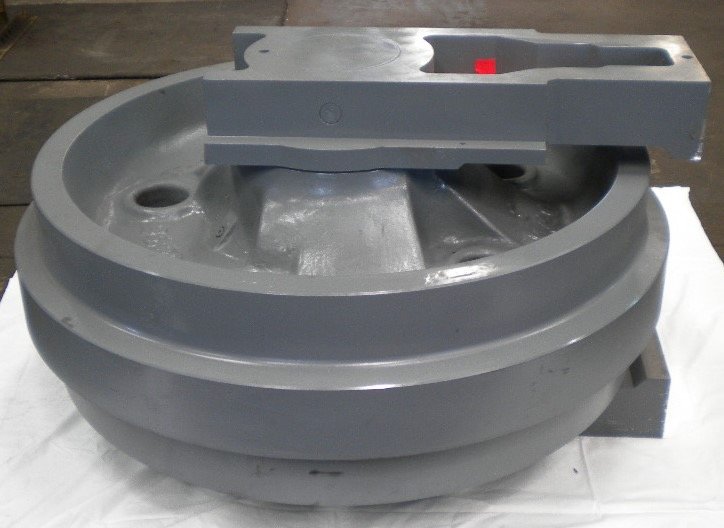

• Full refurbishment of any type of blade including line boring.

• Replacement of front skins, mouldboard sections, endplates

• Repair of rock-guards

• Refurbishment of mounting points

• Replacement of wear plates

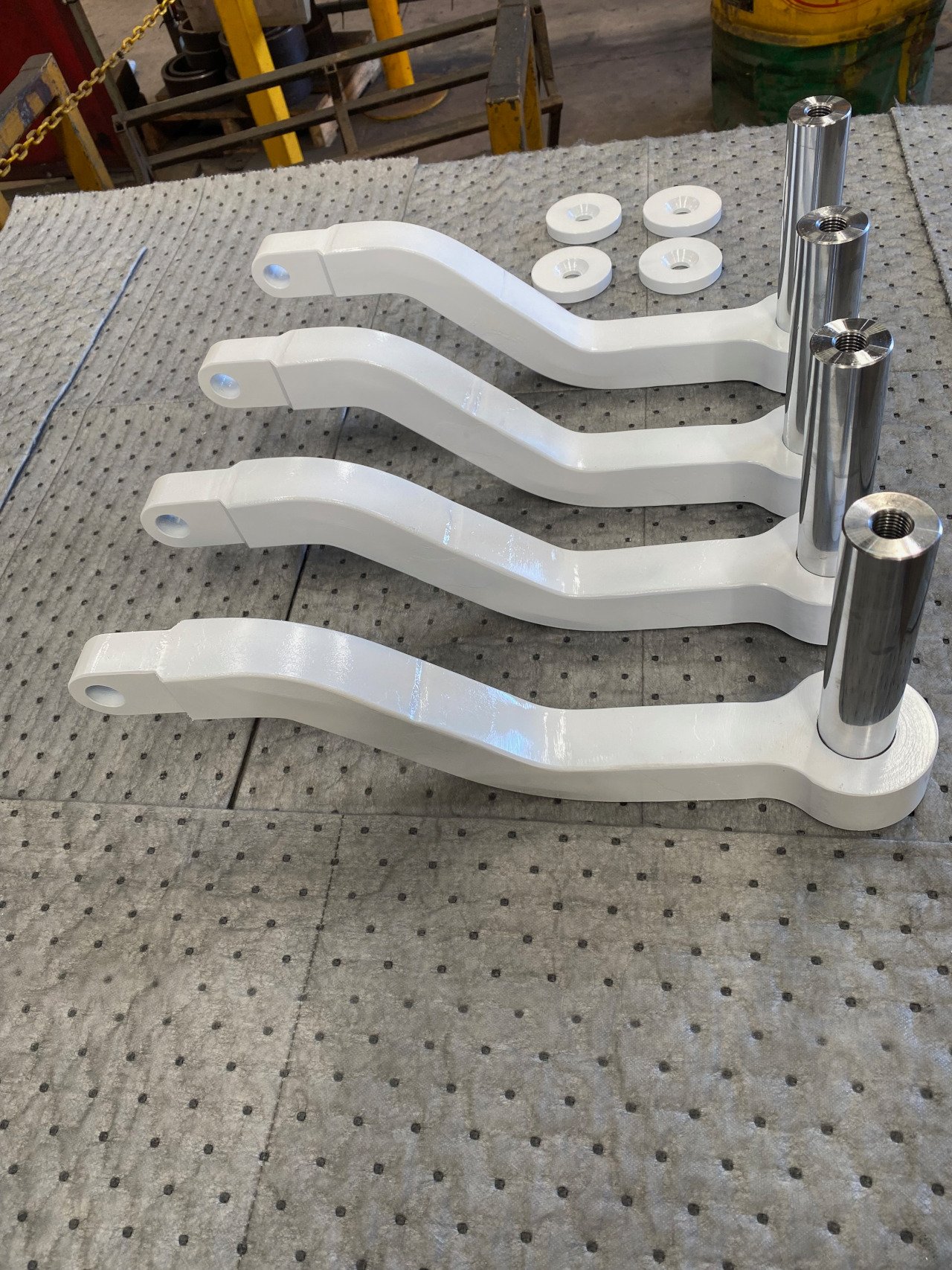

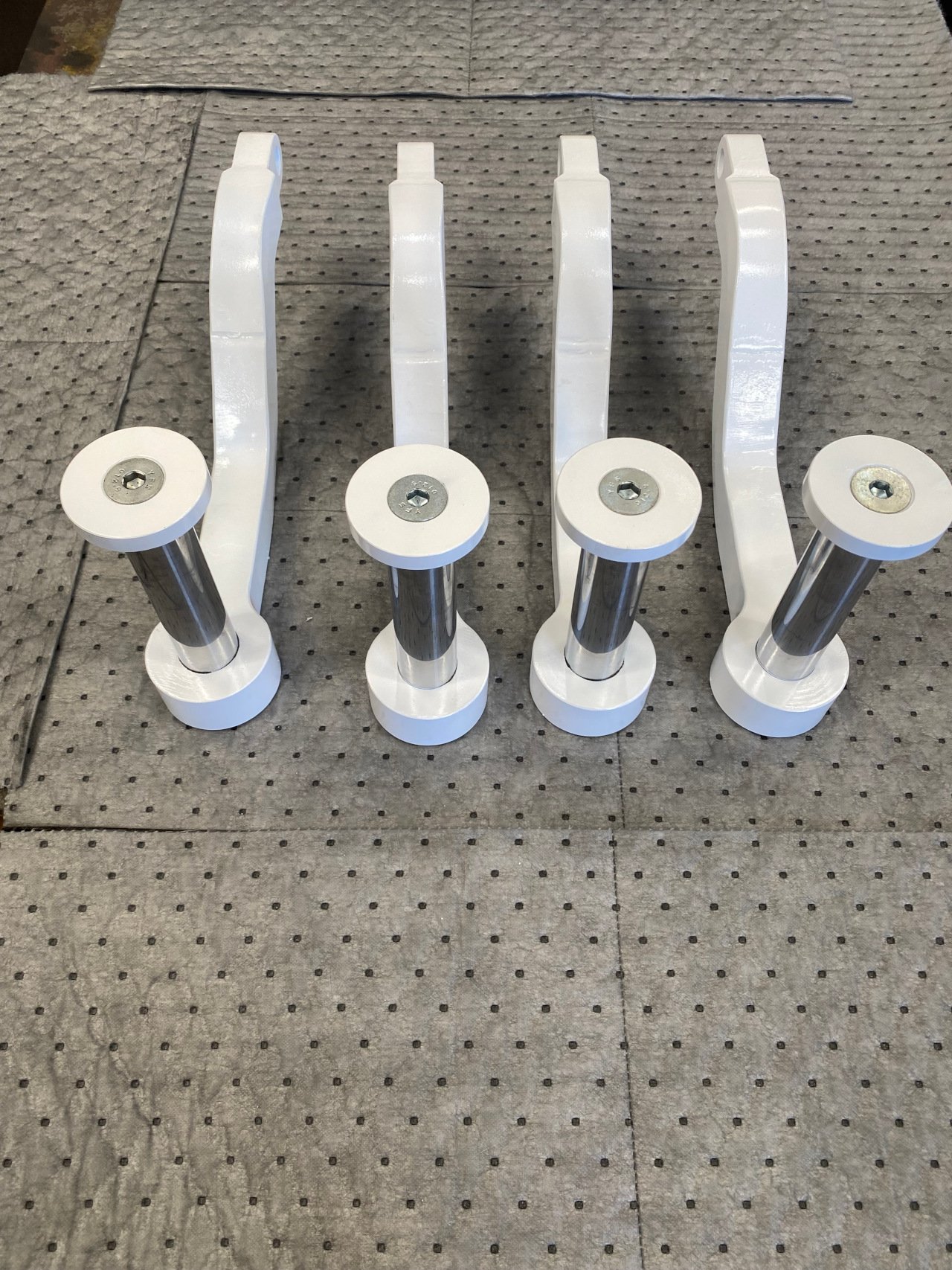

• Push-arm refurbishment

-

The Team at RES has extensive knowledge of mining heavy equipment, the standard of repair required and the importance of delivering on time, every time.

RES Fabrication and Engineering

-

Proficient in commercial and industrial engineering, fabrication, and welding, Richie's Engineering Services functions across all of Central Queensland. Their workforce comprises of experienced boilermakers, fitters, and skilled trade assistants, supported by fully-equipped mobile units accessible around the clock.

-

From emergency on-site repairs of heavy machinery through to custom design and fabrication of tools and parts, RES offers a complete range of engineering, fabrication and welding services. The team regularly service the mining, agriculture and construction industries.

-

In conjunction with welding and fabrication, RES also supplies qualified staff and equipment for hire at competitive rates. The Richie’s Team are competent and friendly, with full OH&S and mining certificates.

ETT OEM Equipment

Richie’s Engineering Services is the official distributor of ETT equipment in Australia. Contact us for all your sales, manufacturing, commissioning and support of ETT OEM equipment.

ETT designs and manufactures a diverse line of open pit mine support equipment and specialised mobile industrial equipment aimed at improving productivity and safety.

Learn more →

Lube Service Trucks

Learn more →

Lowbed Trailers

Learn more →

Water Trucks

Learn more →

Fuel Trucks

ETT Lube Service Trucks

-

ETT’s Lube Service Truck has earned its reputation for reliability in the industry due to its high-quality pumping equipment manufactured by renowned suppliers.

Fitted with top-end components, the service truck meets gruelling industry demands and guarantees speedy servicing to offer unrivalled mining and construction support equipment.

-

The dispensary cabinet houses a series of user-friendly, compartmentalised retractable hose reels, each fitted with a specialised labelled nozzle that can be configured to suit customer specifications.

The primary fluid storage tanks are mounted on the service deck and are filled from a central filling hub with ground-level access.

-

ETT’s Lube Service Trucks are geared to service equipment on-site at their point of operation, thereby minimising downtime and servicing costs.

• Ultra low centre of gravity ensures safer machine handling in motion

• User-friendly ground level compartmentalised hose reels

• High-quality pumping equipment

ETT Lowbed Trailers

-

When it comes to moving heavy machinery on mines and construction sites, ETT’s Lowbed Trailers are the most versatile equipment mobility solution available.

With a loading time as low as four minutes, transporting equipment is safe and fast plus it decreases wear-and-tear on tracked equipment due to excessive tramming.

-

Designed to load from the rear, the lowbed deck lowers to form a ramp with a 4.5-degree incline. The loading process is remote controlled thus, the operator remains out of harm’s way.

-

• ISO3450 braking with OEM truck integration means you stop on a dime

• Anti-jack-knife/truck cab protection

• Rollover protection ROPS for the truck cab

ETT Water Trucks

-

Over years of development, ETT has refined the design of their water truck models.

ETT Water Trucks have earned the reputation of being the most reliable mine support equipment in the field due to superior manufacturing and design innovation, and world-class components that guarantee impeccable performance in harsh mining conditions.

-

ETT prides itself on the ability to design and manufacture ultra-low centre-of-mass off-highway tanker trucks, delivering a key competitive advantage that continues to this day.

Not only do they combat the issue of dust fall-out, but simultaneously address the wastage of a valuable commodity - water.

-

• CDR (Constant Deposition Rate) world-class water-saving spray system

• Low centre of gravity ensures safer machine handling in motion

• Internal baffle system for maximum tank rigidity

ETT Fuel Trucks

-

Refuelling on any worksite is a massive need. Many machines simply cannot be taken away from the work face to travel even short distances to refuel.

ETT’s Fuel Truck is designed for safe and efficient refuelling, providing reliable and fast performance in the most demanding environments on mines and construction sites.

-

Compatible with all major OEM articulating truck models, ETT’s Fuel Trucks are built with an internal baffle system for maximum tank rigidity and longevity whilst ensuring excellent surge control and minimal fluid slosh.

The accessibility of a mobile fuel truck on site reduces downtime between refuelling tasks and ensures that projects remain on schedule.

-

• World-class fuel dispensing systems

• High-quality components and superior manufacturing techniques

• On-site mobile fuel truck reduces downtime